In the competitive electric vehicle (EV) industry, perfecting the battery tray’s aluminum weld design is critical. It houses essential components and safety ensuring precise integration is crucial to prevent potential hazards such as torsion-induced bending of both the battery tray and the vehicle body due to thermal expansion of battery cells.

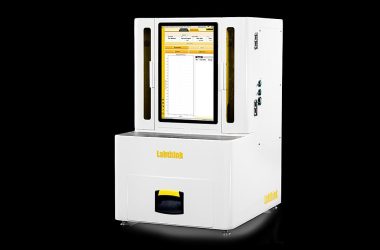

Automating EV Battery Tray Inspection Increases Speed of Information

Related Posts

Energy Costs, EV Growth Drive Changes in Leak Testing Methods

Leak testing applications are evolving rapidly as manufacturers adapt to challenges in electric vehicle production, sustainability, and automation.

PODCAST | Train and Maintain With the Right Software

Quality interviewed the CEO of Spectrum Custom Packaging, our 2025 Plant of the Year, on how to train,…

Rebuilding Boeing’s Quality: A New Approach to Manufacturing Excellence

Boeing needs to improve its manufacturing approach to prioritize transparency and continual improvement, which can also help other…