Aerospace components, varying in shape, size, and material, require specialized inspection methods to ensure quality and safety due to the diverse manufacturing processes involved. Automated Ultrasonic Testing (UT) systems enhance efficiency and defect detection, but effective scanner control, inspection planning, and results analysis are essential to maximize their benefits.

Advances in Automated NDT: Viable Inspection Solutions for Aerospace Applications

Related Posts

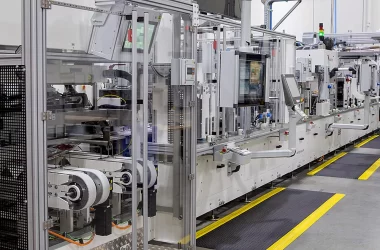

Visualizing Success: How AeroFlexx Enhanced Converter Line Visibility

AeroFlexx, a pioneer in sustainable liquid packaging, partnered with Factory Systems to enhance data visibility on its high-speed…

NEOTech’s Westborough Facility Achieves AS9100 Surveillance Audit

NEOTech announced that its Westborough, MA, facility has successfully completed the rigorous AS9100 Bi-Annual Surveillance Audit with zero…

How AI is Transforming Financial Risk Management

AI in Risk Management Role of AI in Financial Risk Management Challenges of Implementing AI in Risk Management…