A leading aircraft manufacturer faces $27B in losses due to slow supply chain fixes, aggravated by escalating quality standards like AS9102 Rev C. The solution lies in seamless communication of requirements from buyers to suppliers, streamlining operations for all parties involved.

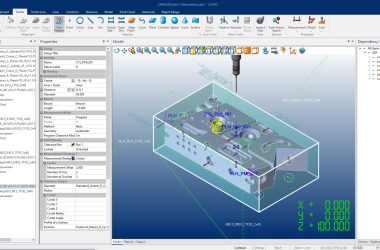

How modern software can transform the supply chain with manufacturing quality at the center

Related Posts

Hexagon Unveils Octave Name for Potential 2026 Company Spin-Off

As Hexagon AB prepares for the potential spin-off of Hexagon’s Asset Lifecycle Intelligence and Safety, Infrastructure & Geospatial…

Keeping Your Machining Processes on Track with 3D Measurement Technology

Machining too many parts that don’t meet specifications means lost time, lost material and lost business. But you…

LK Metrology Measurement Software

British coordinate measuring machine (CMM) manufacturer LK Metrology, Castle Donington, has announced the release of the latest version…

![how-to-speed-up-a-technical-audit-execution-for-faster-seo-growth-[free-templates]](https://prodsens.live/wp-content/uploads/2024/02/20130-how-to-speed-up-a-technical-audit-execution-for-faster-seo-growth-free-templates-110x110.png)